Carbon steel doctor blades provide high hardness and strong wear resistance, ensuring consistent performance across different printing applications. We use high-quality carbon steel sourced from Europe, delivering reliable ink metering and durability. These metal doctor blades feature a polished blade edge that improves ink transfer while maintaining print quality and reducing defects.

With excellent mechanical properties, these blades perform well at various press speeds, delivering stable results even in high-speed printing environments.

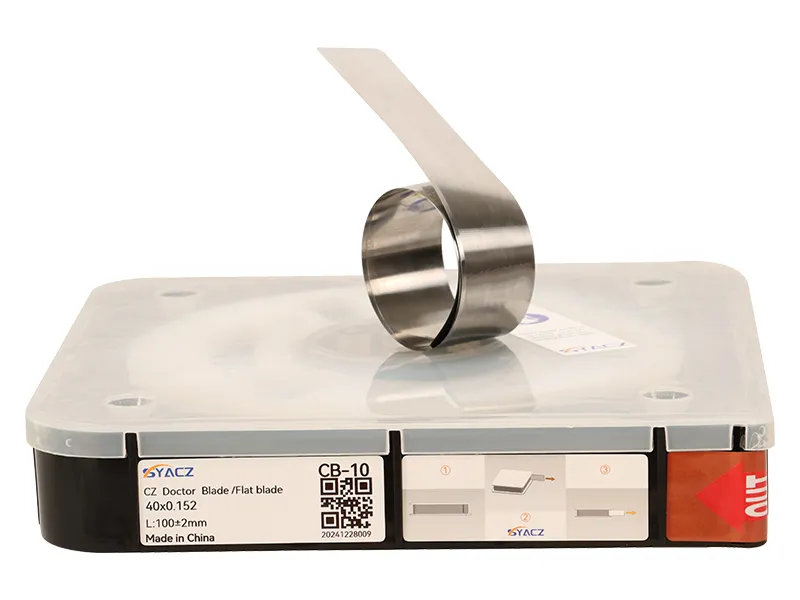

Our carbon steel doctor blades are available in different models to match specific printing needs:

These carbon steel doctor blades are designed for medium-speed printing presses, providing high wear resistance and stable performance.

Ink Types

Specifications

Manufactured from German ZAPP 1274 carbon steel, these doctor blades provide strong wear resistance along with moderate oxidation and corrosion protection, ensuring reliable performance in medium to high-speed printing presses operating at speeds of up to 200m/min.

Ink Types

Specifications

Doctor blades made from ZAPP 2067 carbon steel offer increased durability and wear resistance, and are suitable for medium to high-speed printing at speeds of up to 250m/min.

Ink Types

Specifications

Made from high-quality 20C2 carbon steel, these doctor blades are designed for high-speed printing, handling press speeds of up to 350m/min.

Ink Types

Specifications

Carbon steel doctor blades provide a cost-effective solution for printing applications that require high durability and strong wear resistance. Their hardness and edge stability ensure consistent ink metering, while the polished surface helps maintain clean ink transfer and reduces common printing defects. These blades are particularly suitable for small to medium print runs, offering a reliable balance between performance and affordability.

The combination of hardness and wear resistance allows these blades to maintain uniform ink distribution, reducing streaking, haze, and ink drag. The polished edge minimizes plate wear, ensuring precise ink control and sharper print details. By providing consistent performance throughout extended use, they contribute to overall print stability.

For basic printing needs where cost efficiency is a priority, CB-10 doctor blades are a practical option. With a maximum speed of 150m/min, they work well in gravure, flexographic, adhesive coating, woven bag printing, plastic film printing, cardboard printing, and coating applications.

For short-run applications that demand improved durability and print clarity, CC-20 doctor blades provide strong wear resistance and smooth blade wear. Capable of handling speeds up to 200m/min, they help reduce streaking and haze, ensuring a cleaner ink transfer in gravure and flexographic printing.

Printing conditions involving thicker, more abrasive inks require CZ-30 doctor blades. Manufactured from 20C2 carbon steel, these metal doctor blades support speeds up to 350m/min while preventing ink buildup and blade wear. The polished edge enhances performance by reducing streaking, haze, and ink drag, which is ideal for fine detail, deep-tone printing, and ceramic plate applications.